In today’s business environment, consumers always look for instant results. A simple example is that when they place an order, they immediately start tracking to see when the package will arrive. In fact, no one will place orders without a definitive ETA (estimated time of arrival). This has drastically changed the last mile for the supply chain industry, forcing operations into making faster deliveries and monitoring more accurately to deliver a product to its final destination.

Companies are struggling to keep up with shipping and tracking – they are looking for new methods to keep up with the increasing pace of last mile. As we become more dependant on technology, it comes as no surprise that digitization is the solution. Once digitization is implemented in the supply chain, it revolutionizes last mile, thus allowing accountability and transparency to meet customer requirements more efficiently. It ensures there is no extra stress on the supply chain, which could cause disruptions.

How can last mile improve digitization of supply chain?

Plan and schedule transportation

When it comes to the last mile of supply chain planning, it means the movement of finished goods from the transportation hub to its final destination. To ensure that this process goes on smoothly, you must plan the transportation properly. Even though transportation seems like the most straightforward aspect of the supply chain, as “the hard part is over”, it can cause loads of issues, if not efficiently managed.

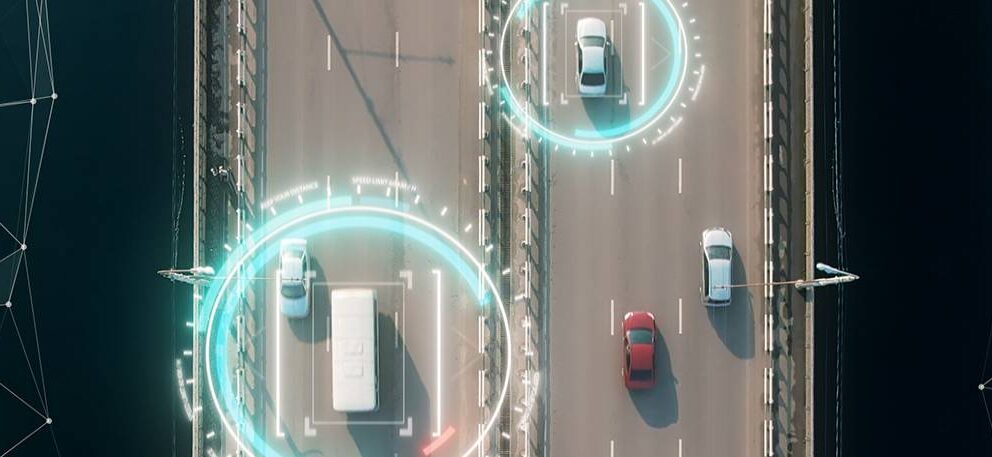

End-to-end efficiency in a supply chain is extremely important for seamless last mile operations. It is clear that with the right transportation optimization software, dispatchers and planners are able to design and optimize the perfect transport scenario. Suitable solutions allow dispatchers to plan and schedule vehicle routing in the network, thus ensuring pickup and drop-off of goods in a timely manner. Using analytics, data integration, telematics, Internet of Things (IoT), and geo-services, you get real-time forecasts. It provides you with the information required to avoid disruptions and make optimal transportation decisions, both in-bound and out-bound. Thanks to smart, accurate, and timely decisions, planning efforts can be reduced up to 60%, while transportation costs can be minimized by 20%.

Keep in mind that automation of digitization eliminates risk of human error, while allowing smarter decisions, via use of parallel processing instead of sequential methods. Data is simultaneously analyzed through one system, rather than requiring coordination from numerous team members. It improves internal communication, while easing exchange of information.

With a digitally transformed transportation system, you can be more confident in your goods’ timely movement from one destination to another.

Keep tabs and monitor in real-time

Apart from reliable transportation, you should be able to track and monitor products as they move through the last mile of supply chain. Multi-dimensional monitoring helps visualize the supply situation, providing transparency when it comes to bottlenecks, inventories, and complete coverage of the supply chain.

While identifying bottlenecks, you can check exactly which orders are affected so you can filter them apart from on-schedule orders and reduce further delays. Moreover, these real-time updates will allow you to update customers as quickly as possible, thus maintaining customer satisfaction.

Monitoring via last mile software solutions help to identify specific problems like bad weather, delays in transportation, and lost cargo, before they even arise. Warnings such as these are critical to avoid disruptions and maintain timely deliveries. This monitoring system keeps tabs on processes in a global environment, be it tracking products by land, air, or sea. It will monitor supply of parts against planned sequence, inventories, and transportation route, ensuring you have eyes on the products at all times. It simultaneously checks your ability to deliver and also the status of products, so the supply chain is up-to-date. Using Anstel’s Last Mile solutions that help to monitor round-the-clock, you can save tremendously in reducing safety stocks and additional transportation trips, allowing you to increase production.

Pay attention to shipping

Transportation and monitoring are two of the major components of last mile, but the primary purpose of last mile is delivering goods to their final destination. Some companies often overlook the importance of their shipping responsibility, falsely perceiving it as being out of a business’s control. In fact, there have been several delays in shipping in the last couple of years due to the Covid-19 pandemic.

While this is an unprecedented side effect, it should not be news for supply chain managers to prepare for the unexpected. To prepare for global delays like this, or even delays of the usual kind, supply chains must have an effective system of managing their shipping process. Digitization of supply chains will help predict delays and quickly resolve them. While it may seem that the solutions for transportation and monitoring overlap with shipping, it is crucial to cover all of your bases.

When it comes to shipping, machine learning has totally transformed supply chains. This is a process where enormous data caches are analyzed to find connections between different sets of information. Shipping involves massive quantities of data, and it can be easy for important details to get lost, resulting in delayed or missing orders. When this happens, business is impacted, which leads to loss of reputation and revenue leakage.

Once machine learning is implemented into the shipping systems, it will use historical data such as past orders, while comparing it with real-time information. It enables standardization of key data points to alleviate some of the complexity of supply chains and last mile delivery. Thus, it pin points the factors contributing to a successful supply chain and continues to implement them. Moreover, it predicts forecasts that let you prepare orders, storage and transportation more accurately, thereby simplifying the shipping process and bringing products to consumers much faster. Added awareness of these factors will allow you to maximize capacity and transportation, saving you valuable time and money while exceeding customer expectations.

Keeping customers happy

The last mile is all about bringing goods to their final destination, but you must not forget what that destination is – customers. The ultimate goal of your supply chain is to maintain and improve customer satisfaction, while encouraging repeat business. By digitizing the supply chain, you provide customers with timely, rapid, and reliable deliveries. Implementation of transportation planning systems, multi-dimensional monitoring, and machine learning, ensures an excellent supply chain performance, which means happy customers at the end of the day. Customers get real-time updates thanks to last mile solutions, regarding order status. They know just what to expect when they conduct purchases. While digitization is crucial for your supply chain and will benefit you in countless ways, it is essential to remember that it is advantageous for customers too, especially in the last leg of their anticipated delivery.

How can transitioning towards digitization help?

Due to volatility of demand and irregular product availability, stock-outs are amongst the biggest challenges being faced by last mile delivery companies these days. Customers have little patience or tolerance when they hear their favorite item is unavailable. It will take seconds for them to switch to a competitor when they encounter a stock-out. After all, there are many active players in the last mile delivery environment.

High seasonality, short shelf-life, and the perishable nature of many products require a lot of precision in purchase order planning. When you work with a trustworthy digital transformation partner, it helps to accurately forecast future demand and product availability, so you can dynamically adjust stock levels to find the right balance between minimizing stock-outs and eliminating waste.

Remember that due to aggressive growth, last mile delivery providers have an incredibly complex network of warehouses, docks, dark stores, and local vendors, usually without adequate planning infrastructure. They usually have limited planning tools and rely heavily on employees for knowledge management. Add to that the abundance of spreadsheets for individual processes, and it is not hard to get lost in the chaos.

Thanks to digitization, machine learning, and advanced analytics, last mile providers can effectively plan all steps of their supply chain journey. It includes forecasting, dark-store replenishment, and warehouse procurement – each step is integrated seamlessly with one another and works in sync to deliver amazing customer service. They can consolidate their entire supply chain network under a single digital platform. The system considers external factors such as weather data, special events, and promotions from various sources to generate actionable insights and automated recommendations to run their dark-store replenishment and warehouse procurement processes.

By utilizing cutting-edge technologies and analytics, last mile providers can survive the ever-demanding challenges of fast growth. Digital supply chain planning solutions offer sophisticated tools to tackle these predicaments rigorously.

The Covid-19 pandemic showed us what it takes to find innovative solutions during challenging times. Supply chains have to maintain stellar performance so companies can continue delivering exceptional customer service, while ensuring their product offerings are accessible, convenient, and fully available at all times. Digitization via last mile is just what is needed in future!

Global

Global Australia

Australia India

India